The Quick Answer… Oh Yes!!

Single-Use Devices (SUD), such as plastic water bottles and Styrofoam packaging, are a major contributor to waste and pollution. They can take years to break down in the environment, and often end up in landfills or becoming litter.

Single-use medical devices have been in the news a lot lately after several high-profile recalls. These devices are often used to treat certain medical conditions, but they can transmit harmful germs if not properly disposed of. In the United States, approximately one-third of all medical devices are discarded after their initial use. This is because many medical devices are designed to last for only a few years and are not designed for repeated use. A new technology called “single-use device reprocessing” aims to reduce the number of single-use devices that end up in the environment.

The practice of reprocessing or reusing products has become increasingly popular in recent years as the environmental and economic impacts of traditional manufacturing practices have come to light. There has been increasing interest in single-use medical device reprocessing because it can help to reduce the number of medical products that are discarded after their initial use.

Read also: What Every Hospital and Surgical Center Administrator Should Know About Single Use Medical Device Reprocessing

The History and Benefits of Reprocessing

Single-use medical device reprocessing is the process of cleaning, disinfecting, sterilizing, and inspecting a single-use medical device so that it can be used again. This process helps to reduce the amount of medical waste produced by hospitals and clinics, and it also helps to save money by using the same devices multiple times. Reprocessing is typically performed by a third party, such as a medical device reprocessor or a hospital engineering department. It can be done manually or with the help of automated equipment.

Medical devices have been reprocessed for many years. The history of reprocessing single-use medical devices can be traced back to the early 1900s when surgical instruments were cleaned and reused. In the 1940s, disposable medical products began to be developed and used in hospitals. However, reprocessing of these products was not common until the 1970s when environmental concerns about the reuse of disposable medical products began to increase.

The economic impact of reprocessing single-use medical devices is both significant and far-reaching. The potential cost savings to hospitals and other healthcare providers are estimated to be in the billions of dollars each year, as the reuse of these devices can result in significant reductions in both capital and operating costs. In addition, reprocessed devices can help to reduce the amount of medical waste generated by healthcare facilities, which can also lead to significant savings.

The environmental impact of reprocessing single-use medical devices is twofold. First, the process of reprocessing creates waste products that must be disposed of in a safe and environmentally responsible manner. Second, the use of reprocessed devices may lead to an increased number of devices being used, which could have a negative impact on the environment if not managed properly.

The main concerns are the generation of hazardous waste, the use of water and energy, and the release of pollutants into the environment. Hazardous waste such as sharp and infectious waste must be properly managed to protect workers and the environment.

Reprocessing Quality and Safety Protocols

Medical devices that are designed for a single-use and are reprocessed for subsequent use present a variety of challenges with respect to quality. When reprocessing these devices, it is important to ensure that all surface areas that may come into contact with patients or the environment are cleaned and disinfected. In addition, it is necessary to verify that the device is properly assembled and functioning correctly prior to reuse. Poor-quality reprocessing can lead to patient infection and other adverse events. To ensure the quality of reprocessing, healthcare facilities should implement a rigorous reprocessing protocol that includes standard operating procedures and quality assurance checks.

There is a consensus that reprocessed single-use medical devices are as safe as new devices if they are reprocessed properly. Devices that have been reprocessed must meet the same safety and performance standards as new devices and must be inspected and cleaned according to FDA-approved protocols. The quality of reprocessing services is regularly audited, so patients can be confident that their devices have been properly cleaned and disinfected.

Hospitals and Surgical Centers Can Start Saving Money This Month

Single-use medical devices can be reprocessed and reused with proper sterilization. This can save hospitals and healthcare providers money, while also reducing environmental waste. It is important to note that not all single-use devices can be reprocessed, so it is important to check with the manufacturer before attempting to do so. By following the proper reprocessing guidelines, healthcare facilities can ensure that reprocessed devices are safe and effective for use.

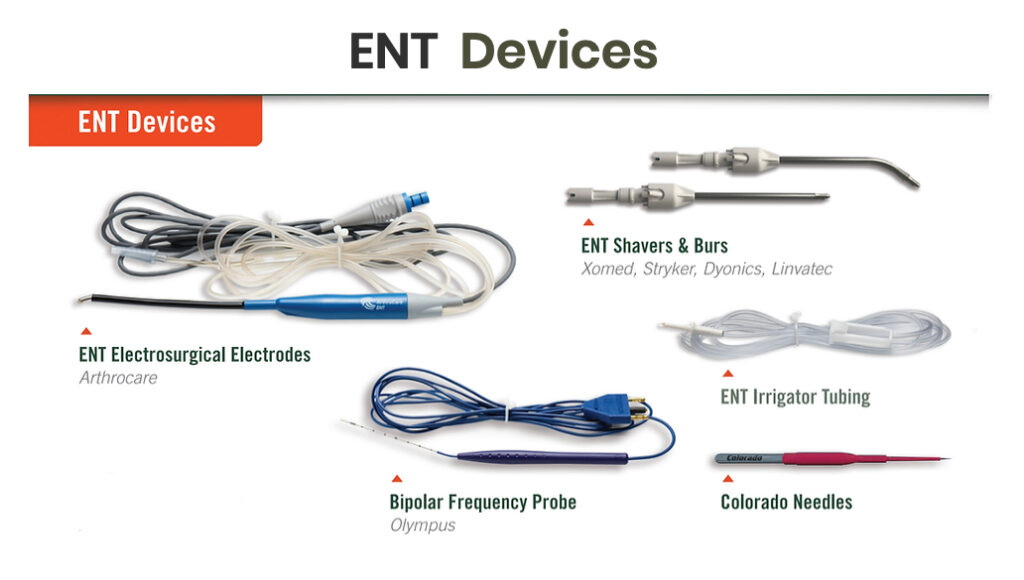

The good news for hospitals and surgical centers in based in the US is that https://coremedsurgical.com has partnered with a national leader, Suretek, Inc. to provide SUD Reprocessing for cost conscious hospital and ASC administrators. They offer a variety of reprocessing services for medical devices used in otolaryngology and general surgery.

Suretek decontaminates used medical devices by utilizing ultrasonic, pressurized steam, and manual cleaning with disinfectants, dual-enzymatic, and hydrogen peroxide. The decontaminated product is polished and cleaned thoroughly and inspected to check its quality. The reprocessed products are then packed, sterilized, and delivered to the healthcare facilities.

For more information in developing a customized reprocessing program for your organization, contact Sean Cherry at today: Sean@Coeurmedsurgical.com