What Every ENT Hospital and Ambulatory Surgery Center (ASC) Administrator Should Know about Single Use Device

Reprocessing

Single Use Device Reprocessing is a reliable and proven method of recycling surgical instruments that were initially designed as disposable medical devices. This process allows hospitals and ambulatory surgical centers (ASC) to reuse these expensive instruments at a fraction of the cost of repurchasing each device for actual single use.

Summary

The hospital or ASC simply sends in their SUD’s to a Reprocessing center and these surgical instruments are reserialized and sent back for further use. Obviously, there is more to it than re-sterilization, but in a nutshell, the process is extremely cost effective for ASC’s that are caught up in the purchase-use-toss cycle of waste.

The good news for hospitals and ASC’s in based in the US is that https://coremedsurgical.com has partnered with a national leader, Suretek, Inc. to provide SUD Reprocessing for cost conscious ENT hospital and ASC administrators.

Example

An ASC averaging 25 sinus or tonsil procedures monthly will typically save more than $3000/month. Larger surgical facilities have been realizing $75,000 or more in annual savings consistently over the years.

Reprocessing: How it Works

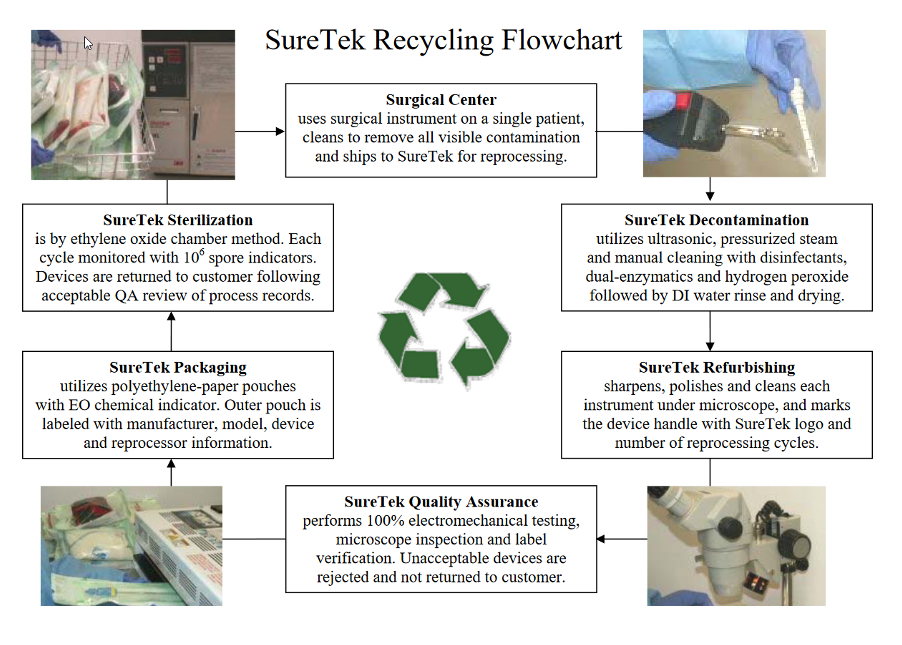

After the ASC sends their surgical disposables for reprocessing, each instrument is tagged with a unique product number and then undergoes a full-cycle decontamination with hydrogen peroxide, enzymatic and disinfectant detergents with manual cleaning, high pressure steam and heated ultrasonics.

This cleaning process is validated in accordance with ASTM E2314Standard Test Method for Determination of Effectiveness of Cleaning Processes for Reusable Instruments Using a Microbiological Method to be effective at removing all visible contamination and providing a 99.9% reduction in pre-sterilization bioburden.

Read More: Can a Single Use Medical Device be Used More Than Once?

All products undergo a 2-step process that includes preconditioning, then ethylene oxide (EO) sterilization using a 3M SteriVac system sterilization. This ensures complete compliance with ISO 11135.

The process is far more technical in nature than described here, but the point is that the process is streamlined and efficient, it is designed to work seamlessly for any surgical center is economically beneficial for any administrator.

Hidden Budget Opportunities – Become the Hero!

The value of this kind of savings is like found money. An administrator can find new purchasing opportunities in the savings without needing to change the purchasing budget. The savings can be used to purchase new surgical devices or operating room devices. Best of all, the opportunity to increase an existing budget via the carve out savings of reprocessing can be realized very quickly.

Our experienced team at CoeurMed will work with your office to implement a targeted device strategy, aimed at reducing procedural costs while maintaining the highest levels of patient care for your center. This focused approach to the reprocessing partnership maximizes surgeon satisfaction and is key to long lasting program. The cost savings are maximized when devices are targeted which yield high surgeon and clinical satisfaction. Many of the below devices will yield more than $100/device when reprocessed:

ENT Electrodes/Coblation Devices:

- ENT Shavers

- ENT Tubing

- Colorado Needles

- CTR Carpal Tunnel Release Blades

- Orthopedic Electrosurgical Ablation Wands

- Arthroscopic Shavers

- Orthopedic Class I Devices

Final Thoughts

The implementation of a SUD Reprocessing program will make any hospital or ASC administrator a hero. The savings that can be captured by the forward-thinking administrator will reap the benefits of additional purchases of needed devices, or simply a savings to the organization’s bottom line. Either way, the benefits are worth implementing your reprocessing program today.

For more information in developing a customized reprocessing program for your organization, contact Sean Cherry at https://coremedsurgical.com today: sean@coeurmedsurgical.com